Iron Filtration

System Operation

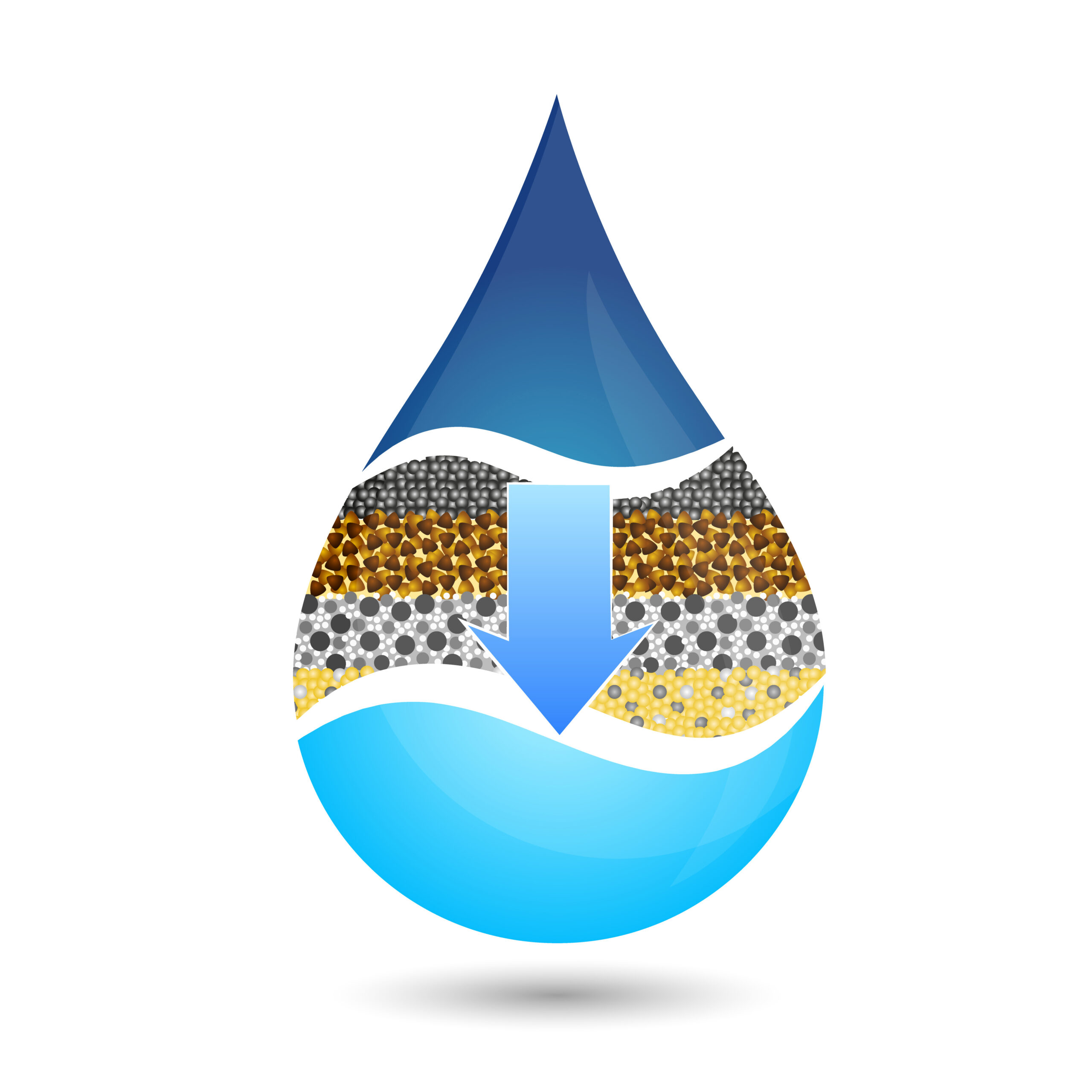

The unique Iron Filtration process offers a method of eliminating soluble iron from groundwater without resorting to large dropout tanks or chemical extraction procedures. The process involves a two-part procedure that includes oxidation and filtration.

- Oxidation: The first step involves injecting air into the raw bore water through a venturi using a booster pump to initiate the iron oxidation process.

- Filtration: Next, the oxidized water is passed through a naturally occurring catalytic media, known as Elliotts Irrigation Filtration Media (EIFM), which traps the precipitated iron.

The filtration unit can remove iron for a period of 15 to 25 hours, depending on the site-specific requirements of each unit. When the operation time is complete, the filtration system automatically backwashes using the bore pump to rid the filter of accumulated iron, thereby recharging it for the next operation period. Finally, a rinse stage is performed to clean the filter before it is returned to service.

Technical Specifications

This method of iron filtration offers a significantly improved approach to treating contaminated groundwater to remove iron and manganese. The process requires oxidizing the water while ensuring that the pH remains unaffected by the filtration process. The efficiency of this aeration and filtration process is superior to conventional treatment systems; it involves less equipment and materials and, most importantly, is chemical-free. In addition, the filtration system produces water that meets the World Health Organization’s standards.

Moreover, Elliotts Irrigation Filtration Media (EIFM) eliminates the need for costly disposal requirements, as it contains no chemical additives and is 100% recyclable. Additionally, EIFM is an eco-friendly alternative for the environment.

Oxidation

The aeration process helps modify the level of volatile substances present in groundwater. This process involves raising the concentration of dissolved oxygen in the water, which reduces the concentration of dissolved carbon dioxide and hydrogen sulphide. The exchange of gases is facilitated through molecular diffusion at a gas-water interface, which becomes more efficient as the surface area increases. An air chamber is created at the top of the pressure vessel to enable this oxidation process. An air release valve located on the top of the filter tank ensures that the size of the air chamber remains appropriate for the specific pressure vessel and system itself.

Filtration

During this stage of the iron removal process, the water enters the Elliotts Irrigation Filtration Media (EIFM) with only diffused oxygen remaining, as excess air and volatile gases have already been released into the atmosphere.

The media consists of an aggregation of disorganized particles that maintain a microcrystalline structure, providing a massive surface area for iron molecules to be absorbed. The absorption of water by the media is between 200 and 250%. The media is unique in its combination of mechanical strength, high specific surface area, and extremely high porosity, increasing iron molecule absorption.

The needle-like structures of the media agglomerate to form bundles that, when dispersed in water, create a randomly intermeshed network of fibres that entrap the water. In addition, the active centres on the surface of the media catalyze iron, leading to the formation of iron precipitates that catalyze the media further, resulting in the faster formation of deposits. This process continues until the filter media requires backwashing.

BACKWASHING: The process of backwashing involves the use of untreated bore water for a period of 10 to 20 minutes, which can vary depending on the specific site requirements. During this process, the filter vessel is subjected to a reverse flow of water, causing the media to float and release the accumulated iron. The resulting backwash water is then discarded. Following this, a rinse cycle is carried out to remove any residual contaminants before the filtration unit is put back into operation.

The filtration unit is managed by a sophisticated Supervisory Control and Data Acquisition (SCADA) system that incorporates a touch panel Human Machine Interface (HMI) for convenient control. This advanced system offers Information Technology (IT) capabilities that enable the management and virtualization of filtration components, operating systems, and applications used for critical functions. The IT domain encompasses user devices, peripherals, and software, including laptops, smartphones, and recording devices.